IQE has used its cREO® platform to create a unique template technology (IQepiMo™) that enables next generation filters.

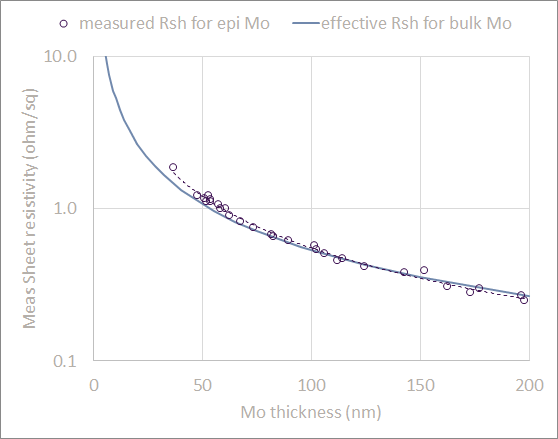

The higher frequencies of 5G present fundamental challenges for incumbent BAW filter technology. Specifically, higher frequency requires that the layers in a BAW filter stack be thinned. For the bottom electrode (typically made of molybdenum), this translates to a layer thickness of < 200 nm. At these thicknesses, the Mo electrodes manufactured with current sputter technology exhibit a sheet resistance that is higher than the corresponding bulk value, thereby creating an electrical penalty that must be accommodated.

IQE’s IQepiMo™ technology eliminates this penalty. Using an epitaxial process at elevated temperatures results in the growth of larger metal grains that deliver improved electrical performance. IQE’s cREO® technology is a critical enabler of IQepiMo™ as it provides a chemical barrier to metal diffusion/reaction with the underlying silicon substrate which would compromise performance.

IQE has demonstrated bulk-like Mo sheet resistivities down to a thickness of 50 nm, far superior to the incumbent sputtering technology. In addition to eliminating the electrical penalty of thin metal electrode layers, the larger metal grains provide an ideal template for the subsequent sputtered piezoelectric layer (AlN), thereby improving its quality. IQepiMo™ offers a route to piezoelectric layers with FWHM < 1°. EpiMo is available on substrates up to 200 mm.